What Are Boom Types of Concrete Pump Truck

Posted On: 18/10/2023 | Posted by: Haomei Concrete Pumps

The boom is one of the most important structural parts of the concrete boom pump. It is mainly composed of basic structural parts such as boom sections, oil cylinders, connecting mechanisms, etc. At the same time, the pump pipe used to transport concrete is also installed on the pump pipe support frame of the boom.

Generally speaking, there are several requirements for the boom: The lighter the weight, the better. The higher the better. The simple the structure, the better. Today we will talk about the structural classification of pump truck booms and discuss what are their respective advantages and disadvantages.

When the pump truck boom is working, it is directly driven by the boom cylinder. The boom can be expanded and folded through the expansion and contraction of the oil rod of the boom cylinder. The boom cylinder is controlled by a hydraulic multi-way valve, and the multi-way valve is controlled by the joystick of the wireless remote control, realizing remote control of the boom.

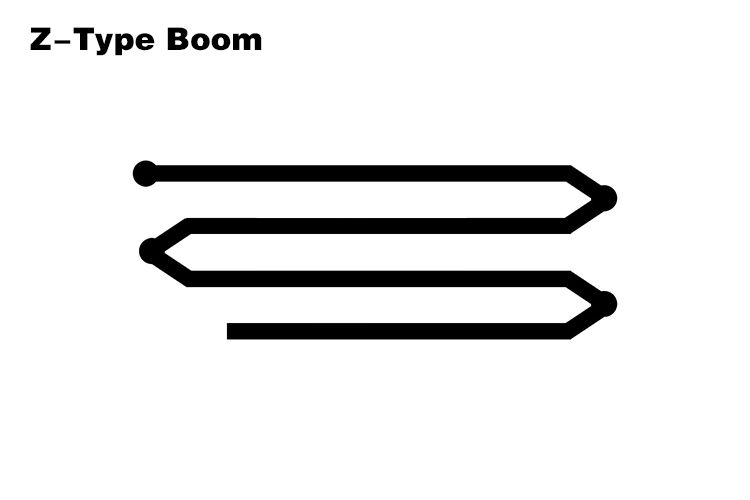

Z Type

A z boom concrete pump usually has less than or equal to 4 sections. Although this Z-type boom does not take up a lot of width space, it does take up more height space. Therefore, it is only suitable for short boom pump trucks. Its advantage is that the structure is simple, the overall boom takes up little space, and at the same time, the deployment speed is the fastest.

As long as one arm is deployed in place, the other arms can be deployed together. Therefore, the time required for boom deployment is the shortest.

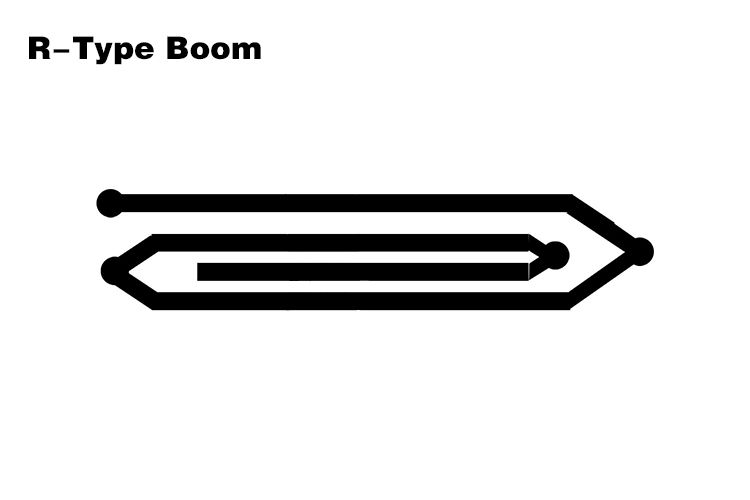

R type

Its structure is more compact than the Z type and the height of the booms is lower. However, when the R-type boom is deployed, one boom needs to be deployed one by one. Therefore, the time required to deploy all the booms is the longest. However, due to its compact structure, its stability is better than the Z type boom.

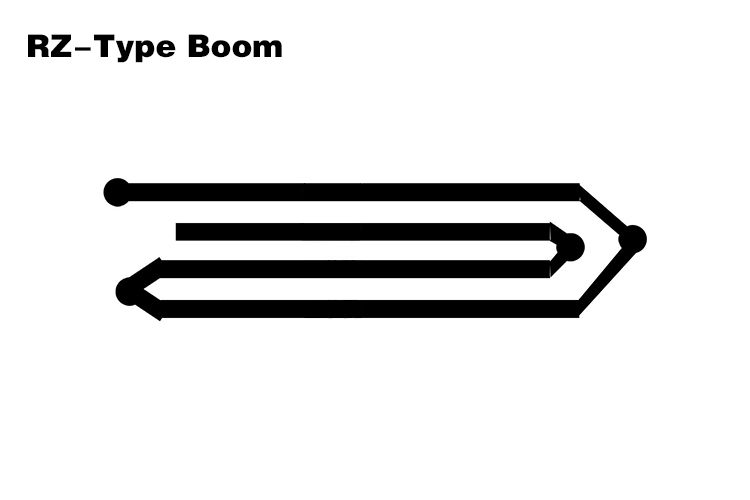

RZ type

The RZ-type boom combines the advantages and disadvantages of the Z-type and R-type boom structures. The boom near the big arm adopts an R-shape, while the boom near the end hose uses a Z-shape. The structure is more complex than the R type.

At present, the RZ-type boom is the most commonly used boom structure because it can be well compatible with 5-section boom pump trucks. The Z-type and R-type can only be compatible with up to 4-section arms. If more than 4-section arms are used, these two structures will be troublesome to use.

Therefore, the small concrete pump trucks will use use Z-type or R-type, such as 33-meter, 37-meter, and 40-meter pump trucks. The RZ-type boom is suitable for concrete pump long boom trucks. Pump trucks with a maximum height of 60 meters or more can use the RZ-type boom structure.

6-section boom structure

After the number of booms reaches 6 sections, there are more ways to combine the booms like RRZ Structure. The 1, 2, and 3-section arms are R-type, the 3, 4, and 5-section arms are also R-type, and the 4, 5, and 6-section arms are Z-type.

In addition, we can also have ZRZ, RZR, ZZR, ZRR, RRZ and other combinations. The greater the number of booms, the wider the range of movement after deployment and the more flexibility. Therefore, more and more boom pressure concrete pumps are now using 6-section booms.

Original source: https://www.concrete-pump-cn.com/a/what-are-boom-types-of-concrete-pump-truck.html

Tags: concrete boom pump,

Previous: What is A Quality Towable Concrete Pump for Sale

Next: How to Operate 57 Meter Concrete Boom Pump

feedom@haomei-machinery.com

feedom@haomei-machinery.com