Diesel concrete pump Pumping Principle by concrete pump manu

Posted On: 17/05/2017 | Posted by: Haomei Concrete Pumps

The diesel concrete pump manufactured by our factory is driven by diesel engine, the main pumping system adopts open circuit, constant power control and has the hydraulic stepless speed regulation and concrete delivery value adjustment functions, the distribution valve adopts S valve. The electric pump is driven by motor, the main pumping system adopts open circuit, constant power control and has the hydraulic stepless speed regulation and concrete delivery value adjustment functions.

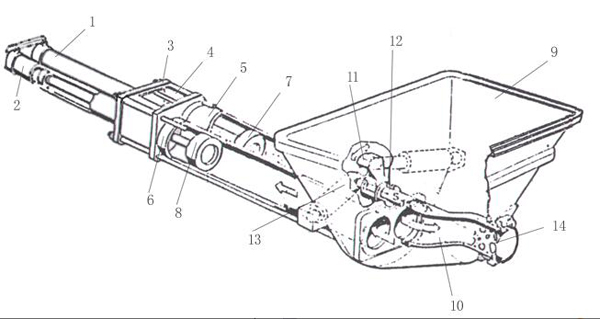

Diesel concrete pump Pumping Principle by concrete pump manufacturer

As shown in the diagram: the pumping mechanism is driving executive mechanism that transfers hydraulic energy to mechanical energy and consists of two master cylinders (1 and 2), water tank (3), reversing device (4), two concrete cylinders (5 and 6), two concrete pistons (7 and 8), hopper (9), distribution valve (10, also named S pipe), swing arm (11), two rotary oil cylinders (12 and 13) and discharge hole (14).

The piston rods (1 and 2) of master cylinder are respectively connected with concrete pistons (7 and 8)and drove by master cylinder piston. One end of concrete cylinders (5 and 6) is connected with the water tank (3), the other end is connected with the hopper. When pumping under low pressure, the rodless cavities of master cylinders (1 and 2) connect. The pressure oil pumped by main oil pump enters in the rod cavity of one master cylinder to draw the master cylinder (1) piston back and push the master cylinder (2) piston forward. The oil in the rod cavity of master cylinder (2) reflows to the oil tank, in this way, a closed circuit is formed. When pumping under high pressure, the rod cavities of master cylinders (1 and 2) connect. The pressure oil pumped by main oil pump enters in the rodless cavity of one master cylinder to push the master cylinder (1) piston forward and draw the master cylinder (2) piston back. The oil in the rodless cavity of master cylinder (2) reflows to the oil tank.

During pumping operation, one cylinder of the master cylinder piston goes forward and the other draws back to drive the concrete cylinder pistons back and forward respectively. The concrete is pumped out when the concrete piston goes forward, and the concrete in the hopper is sucked into the concrete cylinder when the concrete piston draws back, the reversing device installed in the water tank makes the master cylinder piston reverse, in this way, the pumping of concrete cylinder transforms into material sucking, and the material sucking transforms into pumping, continuous pumping is achieved through such circulatory movement.

Through reverse pumping operation, the concrete cylinder at the sucking stroke is connected with the distribution valve, the concrete cylinder at the pumping stroke is connected with the hopper, so as to withdraw the concrete in the pipe to hopper.

Original source: https://www.concrete-pump-cn.com/a/diesel-concrete-pump-pumping-principle-b.html

Tags: diesel concrete pump, cocrete p,

Previous: Buy pump concrete mixer or rent a concrete pump

Next: Forward and reverse pumping state for concrete pump

feedom@haomei-machinery.com

feedom@haomei-machinery.com